Flocon works director shares memories of heavy industry and 'the biggest thing ever to leave Littlehampton’

and live on Freeview channel 276

D.G. (Roger) Martin worked at Flocon Limited, a fabrication and construction company which carried out major heavy construction work.

He said: "In my personal opinion, Littlehampton should be proud to acknowledge that period in its history, in that our company was one of the foremost and prestigious companies of technical and construction abilities in that field and also a major employer of skilled craft personnel, most certainly in Sussex and dare I say the UK."

Advertisement

Hide AdAdvertisement

Hide AdBorn and raised in Arundel, Mr Martin has just completed writing his life story from birth to retirement and it has brought back fond memories of his time at Flocon as part of an ‘extremely happy career’.

The company was formed in a small factory in Harwood Road, Littlehampton, in February 1964 and subsequently transferred to larger premises in Fort Road, Littlehampton, where Mr Martin was works director.

He said: "As a point of interest, that building, which was originally built by our company, is still in existence, although operating as a different business.

"Our company was very highly regarded as a major contributor to both UK and worldwide extremely prestigious projects within the oil, gas, petrochemical, chemical and civil industries of the time.

Advertisement

Hide AdAdvertisement

Hide Ad"It would be rather nice to know if any of those former employees are still with us and in good health, as they were the backbone of the company’s success. I am proud of them, wonderful memories."

The company expanded rapidly after its formation and launched Flocon (Design) Ltd as a further service to the industry. The two companies and Longbourne Engineers formed the Flocon group.

Flocon was started by Mr W.E. Ritson, who served as group chairman and managing director. He had a staff of only three to begin with but this soon grew to 35 employees, with a plan to grow the labour force further to at least double that figure within six months.

The new premises built for Flocon included a first stage factory of 40,000 sq ft which would be used for the fabrication company. Work there was varied, covering a range of work for the petrochemical industry as well as small fabricated components for the building construction industry.

Advertisement

Hide AdAdvertisement

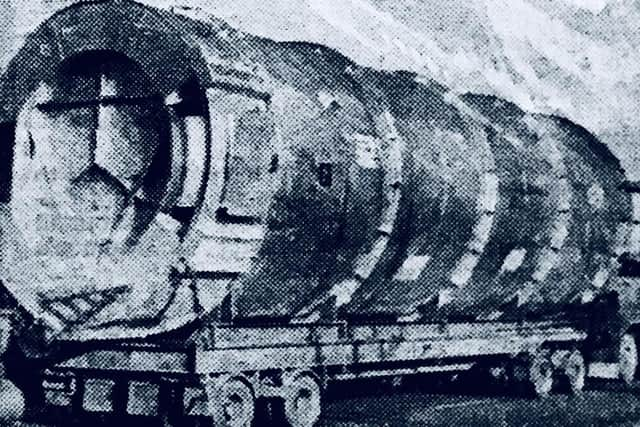

Hide AdFlocon was responsible for one of the largest vessels to be built in the south of England at the time, a 100-ton, 40ft-long crude oil heater for Shell. This was built in Littlehampton before being shipped to the Shell refineries in Singapore, starting with a three-day journey to London.

The petrochemical burner was the biggest thing Flocon made, using steel lined with concrete. It would be filled with crude oil and as it was heated, the various components of the oil would divide into layers, with petrol at the top and tar at the bottom.

Hydraulic jacks were used to raise the burner for a lorry to reverse underneath. The transport travelled at about five miles an hour and was provided with a police escort.

Most of the company's manufacture was for the export market and its goods travelled from Littlehampton to all countries of the world. Shipping the mammoth crude oil heater was almost certainly its biggest challenge, however.

Advertisement

Hide AdAdvertisement

Hide AdThe company progressed rapidly from a small design group to a design and manufacture group that got to the point of having to sub-contract a great deal of its smaller work until the new premises could be completed.

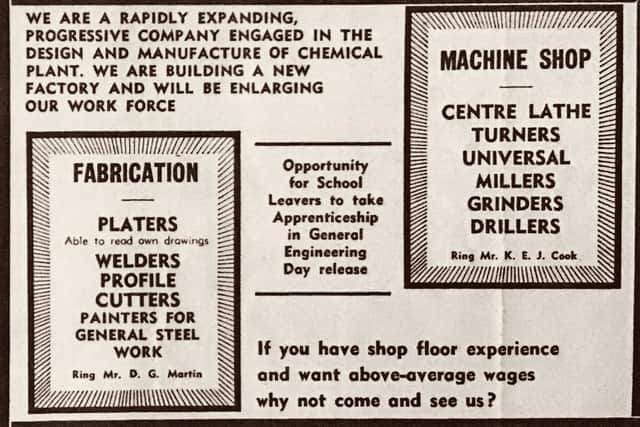

Adverts kept by Mr Martin show the company offered 'good wages', 'guaranteed overtime' and 'good working conditions'. Flocon was described as a 'rapidly expanding, progressive company engaged in the design and manufacture of chemical plant'.

In the machine shop, jobs included centre lathe turners for large and medium size machines, universal millers, grinders, drillers and general machine stop personnel. Meanwhile, platers about to read their own drawings, welders, profile cutters and painters for general steel work were needed in the fabrication company and it was Mr Martin who was responsible for this workforce.

With the company building a new factory and enlarging its workforce, it was an opportunity for school leavers to take an apprenticeship in general engineering on day release.

Advertisement

Hide AdAdvertisement

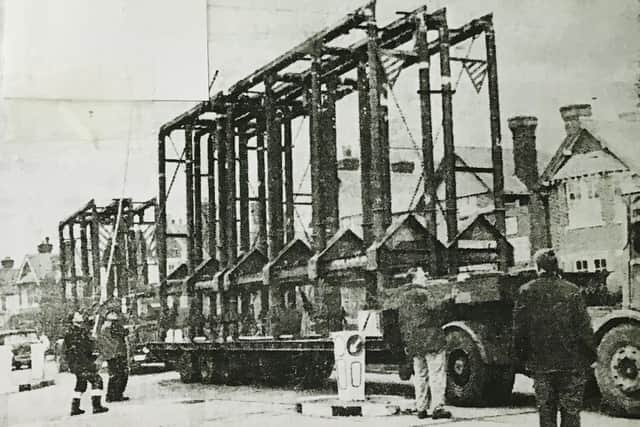

Hide AdOne of the Flocon design specialties was a range of Axial Impeller fans dynamically balanced with aerofoil section blades. These fans offered an economical solution for moving large volumes of air at low pressures.

High efficiency results from the aerofoil blade design and the dynamically balanced impeller provided smooth and silent rotation.

High pressures could also be attained by multi-staging single units. The fans were used in heating and ventilation, equipment cooling, refrigeration, heat exchangers, roof unit radiators, cooling towers, spray booths, machinery space ventilation, marine refrigeration, grain drying, ventilation of poultry houses and piggeries, and dust extraction on combine harvesters.

Mr Martin went on to join a design and engineering company involved in the development of an oil and gas project 120 miles offshore, north east of Aberdeen.

Advertisement

Hide AdAdvertisement

Hide AdHe spent three years on the project and while working offshore, to his surprise, he came across three pressure vessels that had been manufactured by the company in Littlehampton. They played a very important part in the initial early development of North Sea oil and gas.

"At the time of manufacture, we had no idea as where these pressure vessels were destined, as the initial contract for their supply was with a large company based in the Midlands."

Sadly, Flocon Limited went into compulsory liquidation and winding up commenced in March 1974.